Resurfacing a flexible (asphalt) pavement is an expensive undertaking that becomes necessary when the pavement reaches the end of its useful life. There are methods to rehabilitate the pavement, which can extend the useful life as well as have a major effect on the aesthetics of the pavement. Extending the life of the pavement means that resurfacing does not have to be done as often, saving money and placing more time in between the headaches that come with a major intrusive project like resurfacing. Improved aesthetic qualities create a more pleasing visual experience as well as a smoother ride.

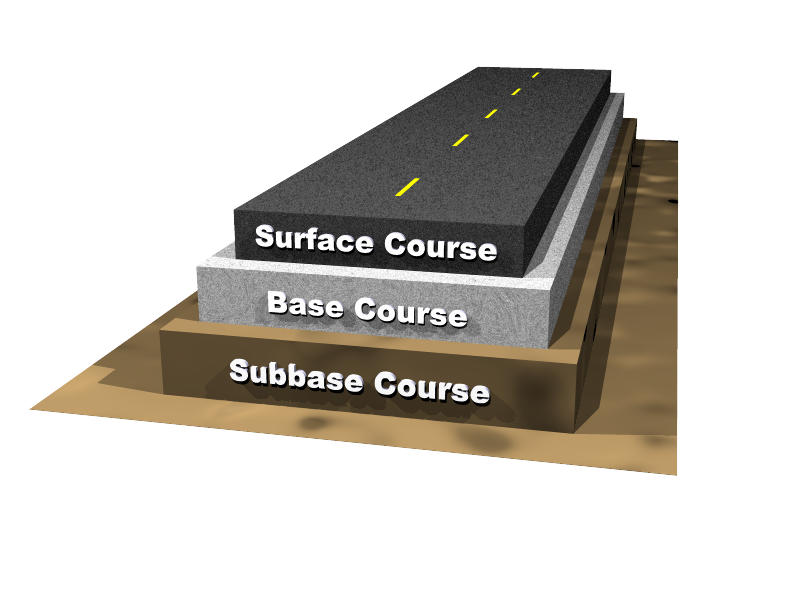

Flexible pavements are typically comprised of multiple layers which help distribute the stresses the vehicles apply to the roadway surface. The top layer is one to two inches of hot-mix asphalt called the surface course (also called the wearing course). This layer is intended to withstand the wear of daily traffic loading. The next layer is the binder course. The binder course is typically a two to four inch thick layer of hot-mix asphalt. The asphalt mixture in this layer contains a higher percentage of large aggregate as well as a lower percentage of asphalt than the surface course. The binder course is the main distributor of load and does not need to have the same durability as the surface course. Beneath the binder course are the base and subbase courses. These courses consist of granular materials and are used to support the above layers as well as to provide drainage for any water that was able to enter the pavement system. The subgrade is the final layer, and is located below the subbase. The subgrade consists of soil, and is used to support the stresses that have been passed down through the layers. The surface, binder, base, and subbase courses are supplemented by seal coats, tack coats, and prime coats, which are thin layers of asphalt mixed with water. The seal coat is used to waterproof the surface course, and also provide friction to prevent vehicles from skidding and sliding. The tack and prime coats are used to bond the adjacent courses together. Each of these layers play an important role in the overall pavement system.

Crackfilling is the most important preventative maintenance task that can be done to asphalt pavement and the association has been attentive to this. Crackfilling is done by placing a sealant inside of existing cracks. This keeps water and other unwanted elements out of the cracks, and can extend the useful life of a pavement system. Periodic crackfilling work should be performed on all pavements to maintain the condition of the pavement. Crackfilling should even be done on pavements nearing the end of their useful lives. Crackfilling pavements that are within a few years of replacement can prevent severe distresses like raveling and potholing which could create a need for costly full depth work when resurfacing. Crackfilling is effective at treating most types of distresses found on asphalt pavements.

There are several different types of cracks or distresses that can occur on an asphalt pavement. Longitudinal and transverse cracks commonly occur due to shrinkage and thermal stresses. These types of cracks are not due to traffic loading. Once the cracks have appeared in the surface course of an asphalt pavement, they become increasingly large over time. This happens because when water freezes, it expands. When longitudinal and transverse cracks are present in an asphalt pavement, water is able to enter these cracks. When this water freezes the cracks will enlarge. Crackfilling will prevent water from entering these cracks and causing them to enlarge. Also, once a crack has formed, factors as common as traffic wear can cause the crack to increase in size.

Reflective cracking is caused by distresses in the underlying layers of an asphalt pavement system. The distress travel through the layers of the pavement system until they reach the surface course. These cracks will tend to enlarge once they reach the surface. Crackfilling is an effective method of controlling surface level reflective cracking.

Block cracking is similar to longitudinal and transverse cracking, in that it is not typically caused by traffic loading. Block cracking appears in the surface course of a flexible pavement system due to temperature cycling, but can become worse from traffic loading. Crackfilling can contain the spread and severity of block cracking.

The most severe type of cracking on an asphalt pavement system is fatigue cracking (also called alligator cracking). Fatigue cracking, as the name implies, is created by repeated traffic loading. These cracks can first appear in the surface course as longitudinal and transverse cracks, but after repeated loading the cracks begin to interconnect, which can resemble the skin of an alligator. Crackfilling is not an effective means of dealing with fatigue cracking. When an asphalt pavement becomes contains a high percentage of fatigue cracking, asphalt overlay or full depth replacement is needed.

Sealcoating is a common preventive maintenance task that can extend the life of pavement. Sealcoating prevents deterioration of the asphaltic binder from sunlight, salt, and traffic. Also, it helps prevent aggregate on the surface course from becoming dislodged, and reduces cracking by filling in minor cracks that are beginning form. Sealcoating is most economical if done early in the life of the pavement. Sealcoating early in the life of a pavement will result in the most favorable results. This is because the pavement is sealed in good condition. If sealcoating is not done until later in the life of the pavement, all existing distresses will be sealed. Sealing over existing cracks can reduce the effectiveness of the seal coat. One or two years after installation is the best time to sealcoat, and will create the most cost effective and quality pavements. Sealcoating should take place every two to three years to continually protect the surface coat of the pavement.

Both crackfilling and sealcoating are methods that can be used to reduce costs in the long run by extending the useful life of existing pavement. This means that more time can pass between resurfacing. Recent contractor bids show that resurfacing costs approximately $6.00 to $7.00 per square yard. Crackfilling can be done for approximately $0.70 per linear foot, based on recent contractor bids. Recent bids for sealcoating came in at approximately $1.25 per square yard. This means that pavement can be sealcoated about five times for the price of resurfacing once. If sealcoating is done every two to three years, the life of the pavement can be expected to increase significantly. If sealcoating is used to extend the life of a pavement segment, there will be substantial savings in the long run.

Effectively using crackfilling and sealcoating can improve both the condition and life of a pavement. This leads to a smoother ride, improved aesthetics, and a cost savings. All three of these are desirable results that can be attained with regular, periodic pavement rehabilitation.